Kurita Sakuganki K.K.

KURITA

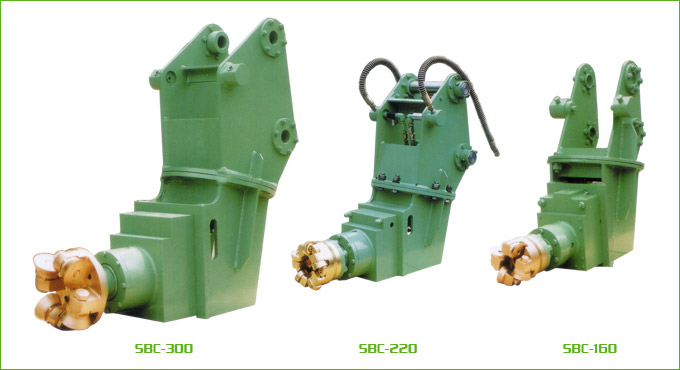

Hydraulic concrete dresser

- Hydraulic concrete dresser

- Hydraulic dresser is a concrete surface shaving machine. It is installed on hydraulic excavator, and operates on oil pressure of the excavator. It can be installed immediately for heavy machineries with breaker piping. It can turn the dresser in any direction with swing platen. The absence of strike makes it low noise and low vibration.

- Cup bit

- 60Φ~100Φ cup bit is installed to shave concrete surface with rotation alone. Bit body has dust collecting holes in the center, and can collect dust with precipitator.

- Cup bit can change positions on 4 faces. The position is changed with a bolt and used until the whole circumference of the cup bit is consumed (exhausted).

Hydraulic concrete dresser specification

| Model | SBC-300 | SBC-220 | SBC-160 | ||

|---|---|---|---|---|---|

| Main body weight (kg) | 330 | 200 | 80 | ||

| Bracket weight (kg) | 190 | 160 | 85 | ||

| Bit rotation (PRM) | 40 | 60 | 80 | ||

| Oil pressure (MPa) | 13 | 13 | 13 | ||

| Oil content (ℓ) | 70 | 50 | 30 | ||

| Bit diameter (Φmm) | Φ108 | Φ70 | Φ60 | ||

| No. of bit X flux diameter (Φmm) | 4ヶ X Φ325 | 5ヶ X Φ234 | 4ヶ X Φ167 | ||

| Capacity (m²/h) | Shaving depth | 5mm | 50 | 34 | 23 |

| 10mm | 19 | 13 | 9 | ||

| 30mm | 5 | 4 | 2.5 | ||

| 60mm | 3 | 2 | 1.1 | ||

| Installation model | Over 0.4 | Over 0.25 | Over 0.05 | ||

Continuous underground wall head chipping

- Chipping work of installing shaft

- Work by installing on 0.25m³ heavy machinery

- Work with low noise as the work takes place in urban areas

- It is free from vibration disease 振動病and can ensure safety, since it is installed on heavy machinery.

Wall surface chipping (breaking)

- Chipping of continuous underground wall of vertical shaft

- Pretreatment to improve adherence of new concrete

- Work by installing on 0.25m³ heavy machinery

- Work with low noise as the work takes place in urban areas

- Install hammer on boom laterally and chip (break) the subject with the vertical motion of boom

Continuous underground wall chipping (breaking)

- Surface chipping of continuous underground wall of anti-flood pond

- Pretreatment to improve adherence of new concrete

- Work by installing on 0.25m³ heavy machinery

All Rights Reserved. ©2013 Kurita Sakuganki K.K.

Steel manufacturing products

- ・Drifter

- ・Residual pig iron removal (discharge) taphole opener

- ・Molten iron tapping hole (taphole (iron notch)) repairing machine

- ・Mixed pig iron (hot metal) separation tub taphole opener

- ・Blast furnace shaft area sampler

- ・Tuyere (twyer) exchanger

- ・Tuyere raceway measuring device

- ・Tuyere coke sampler

Public work related products