Kurita Sakuganki K.K.

- Home

- >>

- Jinzhong City Yuci Marine Hydraulic Pressure Co. Ltd.

- >>

- Hydraulic Cylinder

Hydraulic Cylinder

Hydraulic Cylinder Model Code

Each bushing of hydraulic cylinder has unique structural design, limited on a convex pedestal, uses heat treatment process and advanced processes, and adopts seal structure and seal parts. Anti-leakage is guaranteed under high pressure and harsh environment. Safety and stability of the dump truck is improved with the newly designed limit ring and new high-end sliding material guide ring. Cylinder finish is smooth, and ensures long life and reliability.

160 series hydraulic cylinder

| No, | Format | Stroke | A | B1 | B2 | C1 | C2 | D | K | H | J | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | HY-4TG-E160X3800ZZ | 3800 | 325 | 340 | 470 | 383 | 245 | 57 | M36×1.5/ G1"-6h |

165 | 85 | 1205 |

| 2 | HY-4TG-E160X4210ZZ | 4210 | 325 | 340 | 470 | 383 | 245 | 57 | M36×1.5/ G1"-6h |

165 | 85 | 1305 |

| 3 | HY-4TG-E160X4280ZZ | 4280 | 325 | 340 | 470 | 383 | 245 | 57 | M36×1.5/ G1"-6h |

165 | 85 | 1325 |

| 4 | HY-4TG-E160X4650ZZ | 4650 | 325 | 340 | 470 | 383 | 245 | 57 | M36×1.5/ G1"-6h |

165 | 85 | 1415 |

Cylinder diameter by grade 160 / 135 / 110 / 95 Bushing 245

180 series hydraulic cylinder

| No, | Format | Stroke | A | B1 | B2 | C1 | C2 | D | K | H | J | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | HY-4TG-E180X4280ZZ | 4280 | 325 | 340 | 470 | 383 | 245 | 57 | M36×1.5/ G1"-6h |

165 | 85 | 1325 |

| 2 | HY-4TG-E180X4650ZZ | 4650 | 325 | 340 | 470 | 383 | 245 | 57 | M36×1.5/ G1"-6h |

165 | 85 | 1415 |

| 3 | HY-4TG-E180X5000ZZ | 5000 | 325 | 340 | 470 | 383 | 245 | 57 | M36×1.5/ G1"-6h |

165 | 85 | 1505 |

| 4 | HY-4TG-E180X5390ZZ | 5390 | 325 | 340 | 470 | 383 | 245 | 57 | M36×1.5/ G1"-6h |

165 | 85 | 1600 |

| 5 | HY-4TG-E180X5700ZZ | 5700 | 325 | 340 | 470 | 383 | 245 | 57 | M36×1.5/ G1"-6h |

165 | 85 | 1680 |

| 6 | HY-4TG-E180X6000ZZ | 6000 | 325 | 340 | 470 | 383 | 245 | 57 | M36×1.5/ G1"-6h |

165 | 85 | 1755 |

| 7 | HY-4TG-E180X6300ZZ | 6300 | 325 | 340 | 470 | 383 | 245 | 57 | M36×1.5/ G1"-6h |

165 | 85 | 1830 |

Cylinder diameter by grade 180 / 150 / 125 / 100 Bushing 245

195 series hydraulic cylinder

| No, | Format | Stroke | A | B1 | B2 | C1 | C2 | D | K | H | J | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | HY-4TG-E195X4650ZZ | 4650 | 325 | 360 | 490 | 420 | 280 | 65 | M36×1.5/ G1"-6h |

165 | 85 | 1415 |

| 2 | HY-4TG-E195X5000ZZ | 5000 | 325 | 360 | 490 | 420 | 280 | 65 | M36×1.5/ G1"-6h |

165 | 85 | 1505 |

| 3 | HY-4TG-E195X5390ZZ | 5390 | 325 | 360 | 490 | 420 | 280 | 65 | M36×1.5/ G1"-6h |

165 | 85 | 1600 |

| 4 | HY-4TG-E195X5700ZZ | 5700 | 325 | 360 | 490 | 420 | 280 | 65 | M36×1.5/ G1"-6h |

165 | 85 | 1680 |

| 5 | HY-4TG-E195X6180ZZ | 6180 | 325 | 360 | 490 | 420 | 280 | 65 | M36×1.5/ G1"-6h |

165 | 85 | 1750 |

Cylinder diameter by grade 195 / 170 / 145 / 120 / 95 Bushing 273

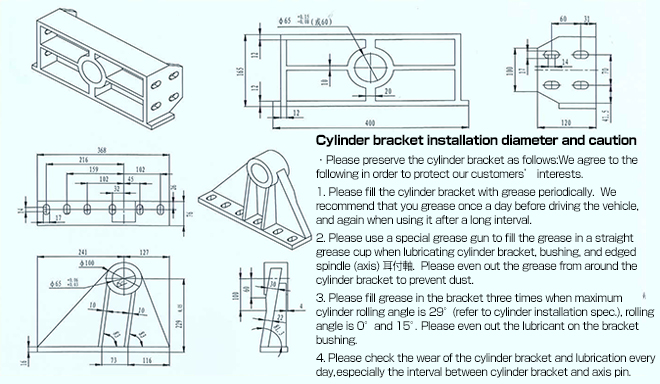

Cylinder bracket installation diameter and caution

・Please preserve the cylinder bracket as follows:

We agree to the following in order to protect our customers’ interests.

1. Please fill the cylinder bracket with grease periodically. We recommend that you grease once a day before driving the vehicle, and again when using it after a long interval.

2. Please use a special grease gun to fill the grease in a straight grease cup when lubricating cylinder bracket, bushing, and edged spindle (axis) trunion. Please even out the grease from around the cylinder bracket to prevent dust.

3. Please fill grease in the bracket three times when maximum cylinder rolling angle is 29° (refer to cylinder installation spec.), rolling angle is 0° and 15°. Please even out the lubricant on the bracket bushing.

4. Please check the wear of the cylinder bracket and lubrication every day, especially the interval between cylinder bracket and axis pin.

Gear pump

| Discharge rate | 100ml/r | Oil temperature | -20-80℃ |

|---|---|---|---|

| Maximum allowable pressure | 28Mpa | Oil inlet pressure | 0.7-3bar |

| Rated pressure | 23Mpa | Oil inlet screw | G11/4″ |

| Minimum rotating speed | 800r/min | Oil outlet screw | G11/4″ |

| Rated rotating speed | 2000r/min | Chuck spindle | 8×32×36×6 |

| Maximum rotating speed | 25000r/min | Weight | 23kg |

Cylinder installation specification

Installation description

All bolts and lock nuts are M16.

Washer is 17×30mm.

Maximum clearance between bracket and cylinder is 2mm.

Locating plate is welded after the bracket is locked.

Caution

1. Offshore hydraulic cylinders can be used only for lift. Other materials cannot be put on top.

2. Working pressure depends on the actual situation. Do not exceed maximum pressure.

3. Keep the cylinder in the air under 2 hours after it extends out.

(Not including chrome plating layer)